If you are installing a shiny new copy of Inventor 2019 with Woodwork for Inventor for the first time then you do not need to follow these steps.

Already using Woodwork for Inventor then read on…

Woodwork for Inventor v9 now uses the JSON database platform instead of the Microsoft SQL Compact Edition and the developers have built in some migration tools to help automate the transition. There are various benefits for this change and I talk about them in my What’s new in Woodwork for Inventor v9 blog post.

As with any system upgrade, two things to consider here. Are you migrating to W4I v9 from W4I v8 on the same version of Inventor 2018? or are you jumping straight to Inventor 2019 with v9? The following will give you some guidance but always make a backup of your data before doing anything.

Make a copy of C:\Users\Public\Documents\Woodwork for Inventor and your project CAD data files.

Installing W4I v9 from W4I v8 Inventor 2018 – Auto Migration

Download your Installation executable Woodwork_for_Inventor_v9.0_2018.exe from your account and obtain your new v9 serial number.

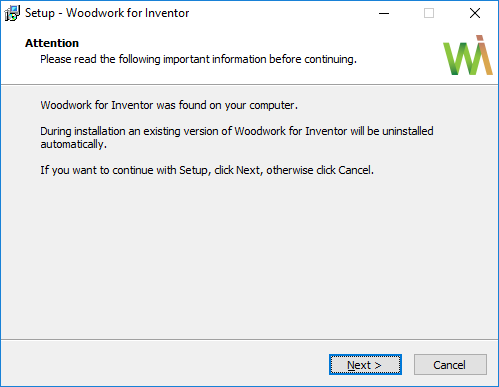

Run the installer with Admin Rights.

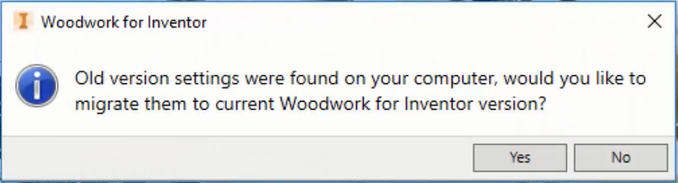

Follow the prompts and W4I will auto migrate your settings.

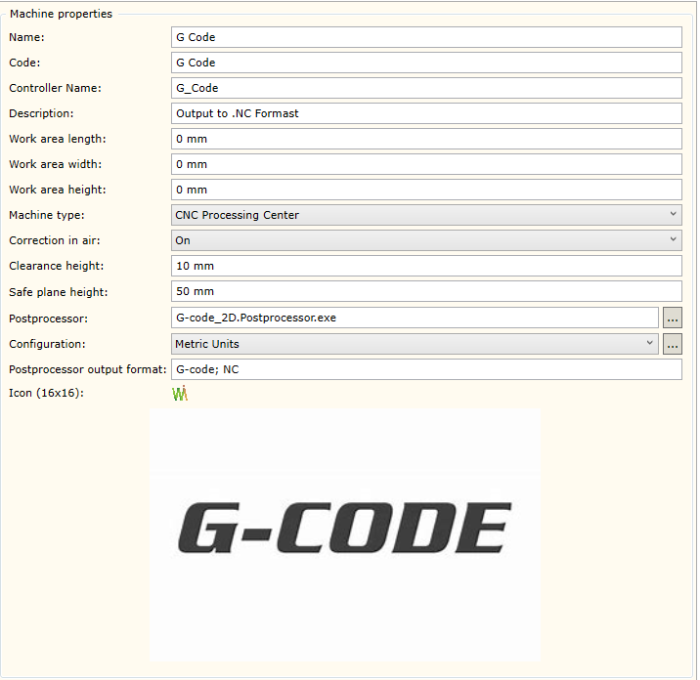

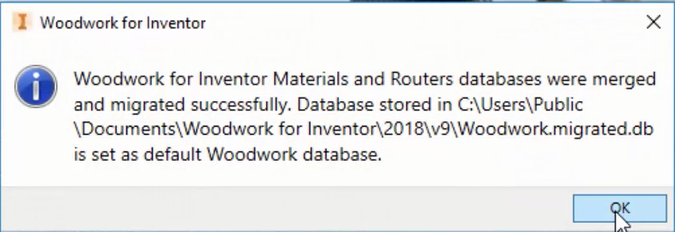

Finally your materials & and routers will be migrated into the new JSON platform database.

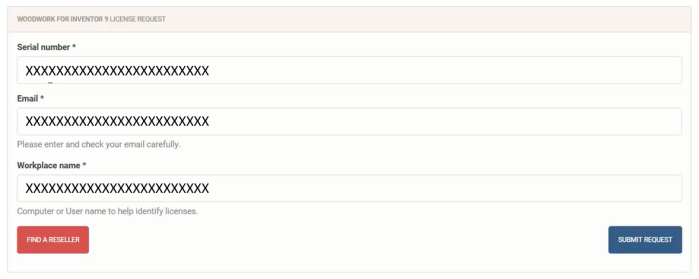

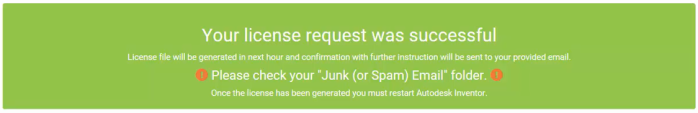

Activate online by entering your new serial number. Each major release gets a new serial number. Enter your email and give your PC a name so that it can be identified should you wish to release the licence to transfer to another machine in the future. Simply submit your request.

You can shutdown Inventor and restart your licence should now be active.

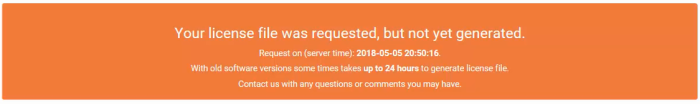

If it’s not yet active, and you try and request you will receive the following message.

Installing W4I v9 with Inventor 2019 – Will be seen as a new Installation and will require Manual Migration.

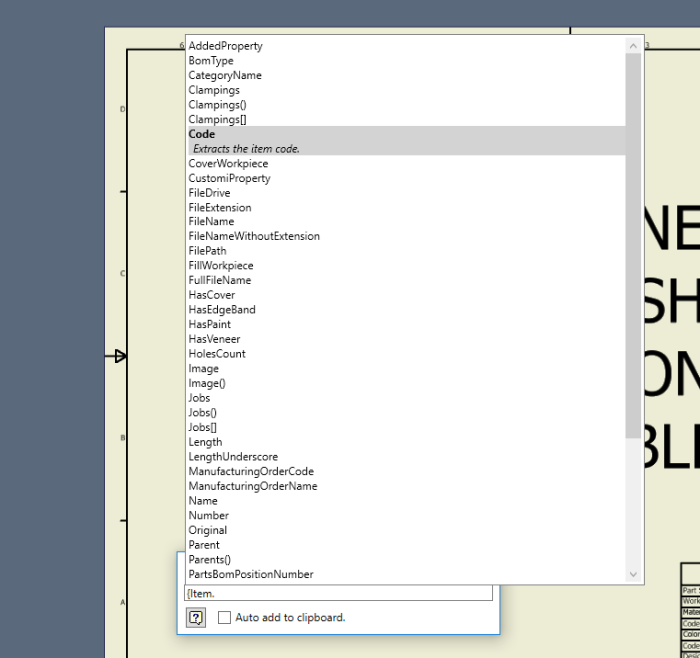

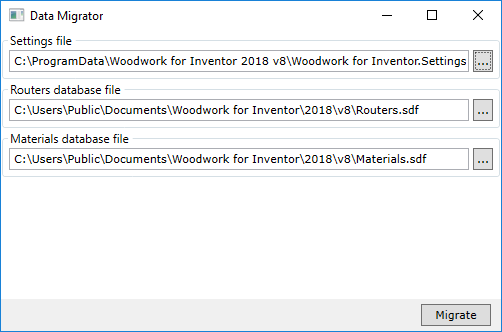

Navigate to C:\Program Files\Woodwork for Inventor 2019 v9\DataMigrator.exe and run the Data Migrator tool. Map your previous installation settings, routers and materials. This folder could also be an earlier version, for example v7.

Once migrated, you should be ready to go. Other files that may need to be copied to complete the process would be:

C:\Users\Public\Documents\Woodwork for Inventor\2018\W4INV Material Library.adsklib or your custom named library

to C:\Users\Public\Documents\Woodwork for Inventor\2019\W4INV Material Library.adsklib

You should now be able to start using Woodwork for Inventor v9.