Happy Holidays from Living on the Edge Band and may you all have a great 2020.

Voronoi Trees this year!!! Download the STL from my GrabCAD account. https://grabcad.com/library/xmas-tree-voronoi-1

Happy Holidays from Living on the Edge Band and may you all have a great 2020.

Voronoi Trees this year!!! Download the STL from my GrabCAD account. https://grabcad.com/library/xmas-tree-voronoi-1

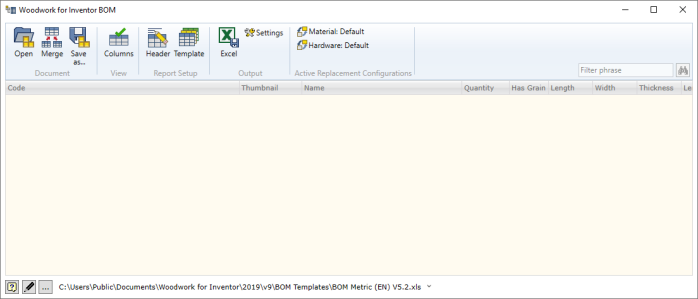

At times you may want to save, open and even merge BOM information using the BOM specification tool. Normally this is accessed via the CAD interface but there is another way.

Locate the executable C:\Program Files\Woodwork for Inventor 2019 v10\Woodwork4Inventor.BOM.exe

Create a shortcut on your desktop.

Once you run this app, you should see the BOM Specification dialogue appear as below.

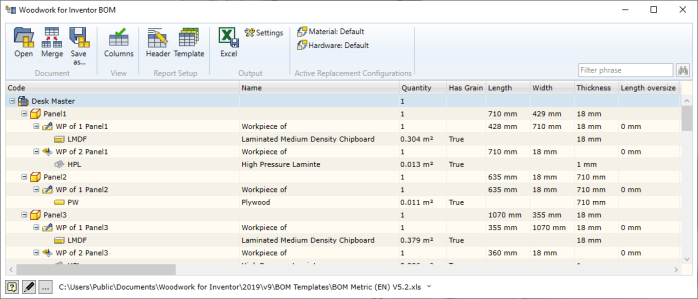

It’s possible to create a snapshot view of your BOM using the save BOM function.

It will create a file with a .wbom extension which Can also be used to launch the BOM specification.

This will show an identical view of the BOM complete with the ability to export to Excel.

Well……. why not?

I’ve been using 3D CAD for more years than I can remember and keep “dipping my toe in the water” as it were, looking at what Fusion 360 has to offer alongside my trusty Autodesk Inventor modeller! Initially I was raving on this blog about taking Inventor models and rendering them with Fusion 360 because you could queue them up whilst they processed in the cloud, freeing me up to do other tasks and the quality seemed to have an edge over what Inventor could achieve.

Now there is a lot of noise about “Generative Design” at the moment and thought it’s worth a look to see what I could achieve with little knowledge and some instinct or “was that the “Learning Guide” appearing on the right of my session”?

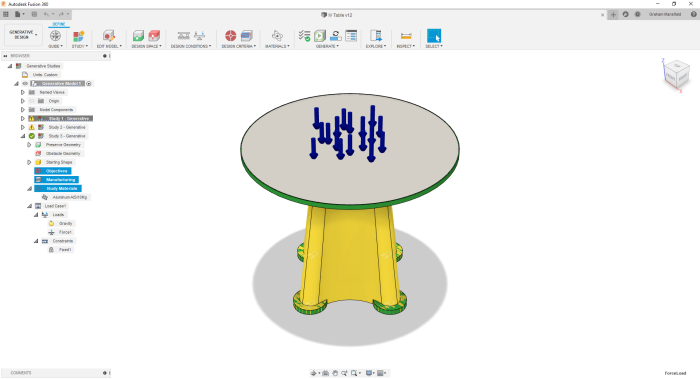

Table Support

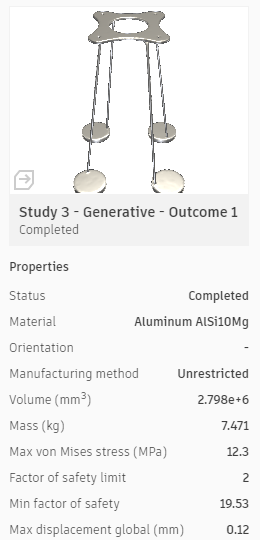

The Table support with a simple Aluminium cast base, with a wall thickness of around 10mm was a simple idea. A lot of these bases are usually ornate and cast in Aluminium, so I was interested to see what it could come up with.

Define some Objectives such as minimise Mass or Stiffness, Safety Factor. Options for Additive, Milling or casting processes could be assessed.

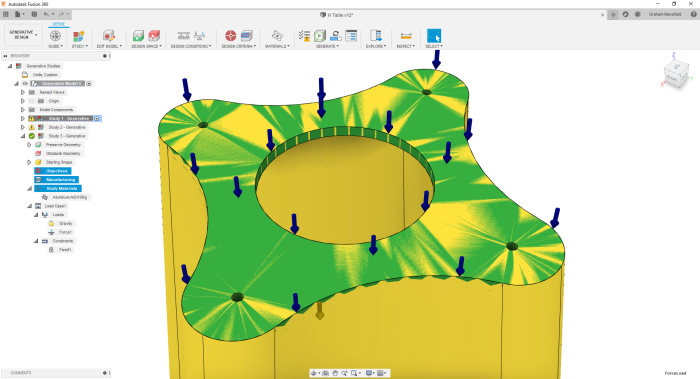

Mark the bodies in your model you wish to Preserve (Green) to keep in your design Which won’t change such as the feet positions and table top. Next would be Obstacle (Red) geometry such as empty spaces. I didn’t actually specify any on this study. Then finally the Starting Shape (Yellow). This was really the main area of focus.

Chose your material if not already assigned and Load your design with a Force and Fix the feet so they don’t move. Then you can submit to generate a design and follow the generate status. This process takes a few hours to complete and the output called an outcome will be displayed.

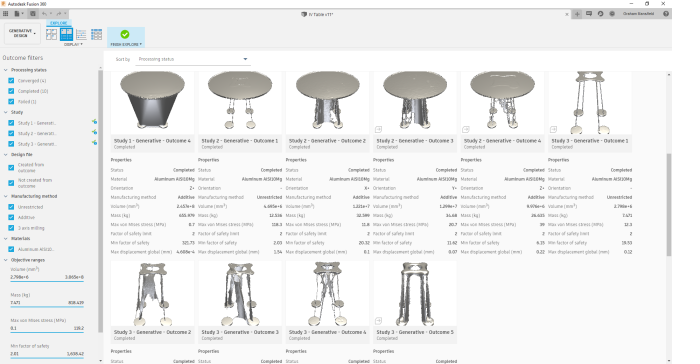

Each outcome will display Mass, von Mises stress and max displacement. The selected outcome can be previewed by rotating & zooming around the model tracking the different iterations at the base with a slider.

Lightest was only 7.5kg but a design that looked interesting was an acceptable 14kg once I machined the top and feet faces flat.

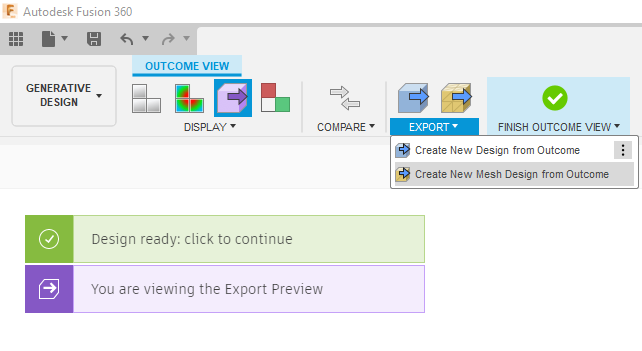

When happy that’s the design you want to work with, the finished results can be created into a new design within Fusion 360 but this will take a short time whilst it’s generated in the cloud.

In the industry I work in, I’m not sure how many times I would embark on using these tools, but for Aerospace, Automotive and Machinery Design there could be great designs that could be made. You will need some cloud credits to use this functionality, typically at the time of writing:-

Generate a study = 25 cloud credits

~100 outcomes, covers 14 Manufacturing types, 7 materials

Download an Outcome as Solid CAD for editable geometry = 100 cloud credits

Why not take advantage and give it a FREE try like I did? You currently get UNLIMITED try’s with Generative Design, until 31st December 2019!!

Enjoy!

Came across WRP Timber Mouldings Ltd trade supplier’s website www.wrp-timber-mouldings.co.uk the other day. It’s a great reference resource for CAD moulding profiles with lots of other interesting tips on the site and of course you can easily order the profile reference from the part number if needed.

https://www.wrp-timber-mouldings.co.uk/download-cad-files

https://www.wrp-timber-mouldings.co.uk/download-cad-files

TIP When using with Inventor, don’t forget to make sure you use a sketchblock when placing in the sketch environment, it will be easier to rotate and position.

Disclaimer

I have no connection with WRP Timber Mouldings, products or services but thought it worth sharing!